How to Make Doped Tungsten Wire

There are many classes of finished wires including nail wire, telegraph and telephone wire, fence and rope wire, spring and musical wire and hundreds of miscellaneous and specialty wires. Almost all of these products are made from the wire rod coils.

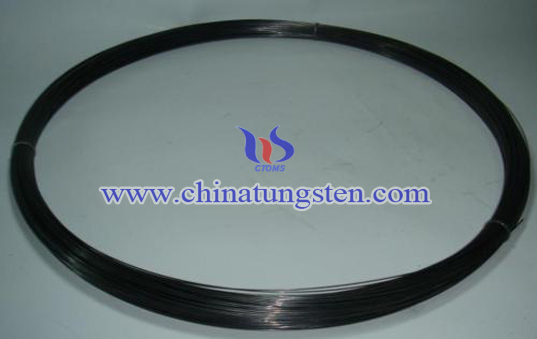

Doped tugnsten wire require to be made through these processing procedures of coatings, heating, tempering, drawing, and finishing.

The first step in doped wire drawing is cleansing the scale, rust, and dirt from the coils by bathing the coils in a hot acid for 15 to 30 minutes. After rinsing with water, the coils are dipped into vats containing hot milk of lime leaving a whitish coat that is baked onto the wires for protection and lubricant.

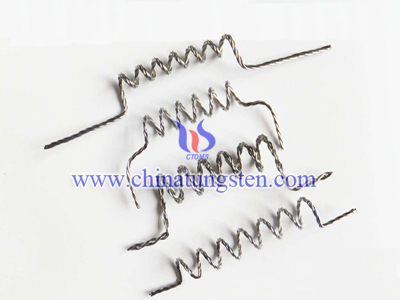

Then heat the doped tungsten wire to a red heat,so that it can be molded to specific shape easier.

Finally drawing through diamond dies of a tool that consists of a highly polished, shaped hole through which doped tungsten wire is drawn to reduce its diameter.

During the process, the wire is hot, while the temperature is still below the recrystallization range, so the process is sometimes called as hot cold-working.Accordingly, as the cross-sectional area is reduced, strength and ductility increase. The as-drawn wire at finished size subsequently may be cleaned, straightened, or annealed.